By merging eologix and Ping Services into one company, we aim to become the world’s leading provider of rotor blade monitoring for wind turbines with our smart sensor systems, thereby increasing the efficiency of wind energy production.

Why eologix-Ping sensor systems?

Optimum performance for your turbine

Ensuring safe wind turbine through continuous monitoring

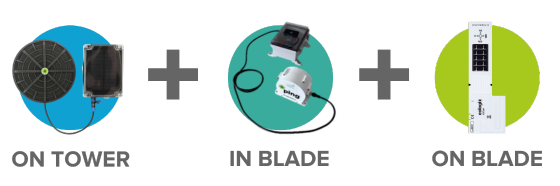

We combine our services to create a holistic monitoring system that allows wind turbine operators to monitor the condition of the rotor blades with “hands, ears and eyes”, so to speak. This is made possible by our proven sensor systems for blade damage detection, ice detection, pitch angle measurement and lightning strike detection.

Fully automated operation under icing conditions

Temperature measurement for preventive heating

Do you have a heating for rotor blades? The measurement of the surface temperature at each sensor unit offers the possibility to monitor or evaluate the effectiveness of a rotor blade heating system. Depending on the manufacturer, the measured temperature values can also be transferred to the SCADA system of the wind turbines.

Continuous monitoring of relative pitch angles

The on-blade sensor system detects relative pitch angle errors as they occur through continuous measurement, in contrast to measurements taken from the ground, thus preventing further damage and subsequent costs.

Reliable damage detection

The on-tower and in-blade systems utilize sound emissions or noise from damage to detect potential issues. By analyzing changes in the sound patterns, these advanced systems can accurately identify the type of damage, enabling prompt initiation of appropriate measures.

Lightning detection system

With this lightning detection option, you will receive lightning strike alerts within 30 minutes, precisely identifying which of your wind turbines has been affected.

We boost sustainable technologies

With our sensor technology, we ensure that wind turbines run optimally in all weather conditions and achieve optimum performance. This is how we create sustainable values for our customers and for the environment.

Innovative sensor technology

Maximizing the annual energy yield of your wind turbines relies on their proper functioning and swift detection and repair of any damage or rotor blade misalignment. Our unwavering commitment is to ensure the best possible performance and efficiency of your turbines, empowering you to harness their full potential.

On-tower monitoring

The on-tower system continuously measures and analyzes the changes in the sound generated by blade damage. It is attached magnetically to the base of the tower of the wind turbine at a height of approximately four meters.

In addition to blade damage, the system can also detect lightning strikes. With this system you will receive lightning strike alerts within 30 minutes, precisely identifying which of your wind turbines has been affected.

In-blade monitoring

The in-blade system is installed at the blade access panel, or within the blade depending on preference. There it uses sound emission to detect root zone structural damage.

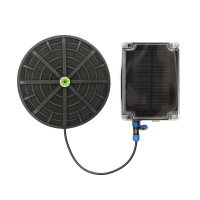

On-blade detection – directly on the rotor blade surface

The on-blade sensor system is installed directly on the surface of the rotor blade. Leveraging cutting-edge technology, it offers reliable icing detection, precise surface temperature measurement for preventive heating, and the capability to identify even the slightest rotor blade misalignments under different turbine operating conditions.

Key factors that set it apart include:

- Energy buffer with rechargeable battery (for +1,000 hours)

- Energy source thanks to flexible solar cell

- Ice detection directly on the blade surface

- Temperature measurement with an accuracy of ±0.25°C

- Inertial data thanks to high resolution inertial measurement unit

- Wireless data transmission with a minimum range of 250m to the base station

Get a quote

Inquire today. We will be happy to evaluate your project.

You will receive a suitable offer and a free consultation from us.

Save on your next monitoring project with our innovative sensors for holistic blade health monitoring.