Imbalances on wind turbines: causes, effects and solutions

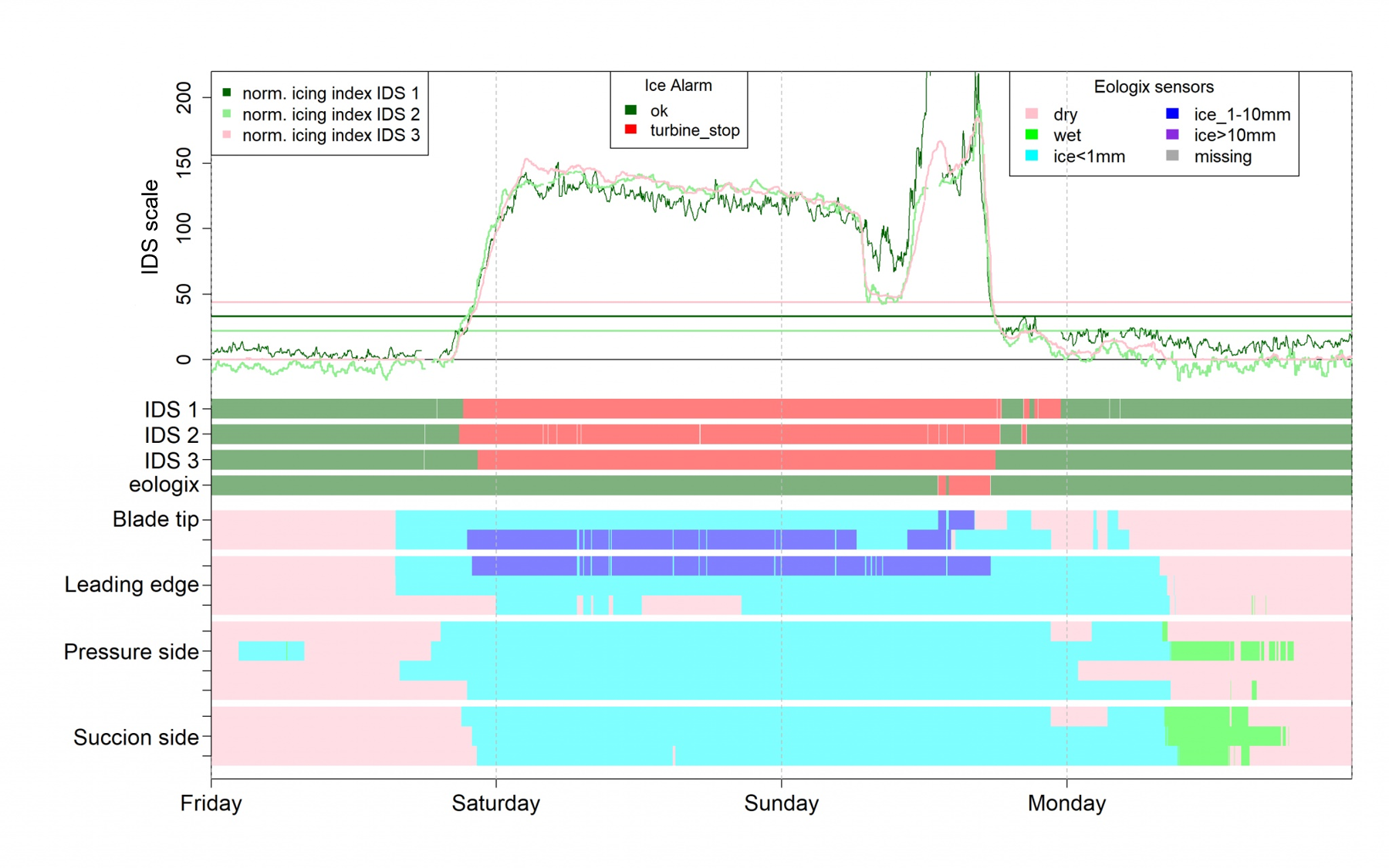

To ensure efficient and reliable power generation by wind turbines, they must be regularly maintained and inspected to detect and correct potential problems such as imbalances. Basically, there are two types of imbalances that can occur in wind turbines: mass imbalance and aerodynamic imbalance